With the continuous in-depth development of industrial automation, the application fields of retractable electric cylinders will be further expanded. In terms of performance improvement, the application of new materials and new processes will enable retractable electric cylinders to achieve greater breakthroughs in load capacity, precision, and response speed to meet more complex and higher-precision work requirements.

The process optimization strategies for retractable electric cylinders in rubber machinery are as follows:

Optimization of Control Algorithms

Adopting advanced control algorithms can effectively improve the control precision and response speed of retractable electric cylinders while reducing energy consumption. For example:

- Introducing adaptive control algorithms to adjust the control parameters of retractable electric cylinders in real time according to the load changes and operating status of rubber machinery, ensuring the cylinders always operate in the optimal state.

- Using predictive control algorithms to forecast changes in production processes in advance and adjust the actions of retractable electric cylinders accordingly, enhancing the system's response speed.

- Optimizing motor drive control strategies, such as vector control and direct torque control, to improve motor operating efficiency and reduce energy consumption.

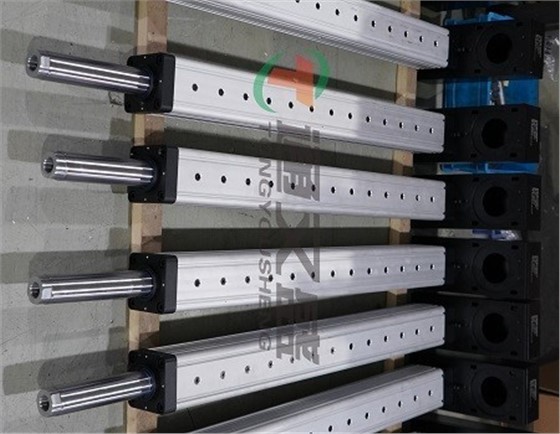

Improvement of Structural Design

Optimizing the structural design of retractable electric cylinders can enhance their precision retention and load adaptability. For example:

- Using high-precision lead screws and nut pairs to improve transmission accuracy and wear resistance.

- Adding guiding mechanisms to enhance stability and anti-eccentric load capacity.

- Optimizing the heat dissipation structure to reduce thermal deformation of components caused by temperature rise, ensuring precision and reliability in high-temperature environments.

- Reasonably designing the external dimensions and installation methods based on the load characteristics of different rubber machinery to ensure good matching with equipment.

Selection of Suitable Materials

Choosing appropriate materials can improve the performance and service life of retractable electric cylinders. For example:

- Using high-strength, wear-resistant alloy steel for lead screws and nuts, combined with surface treatments (such as hard chrome plating or nitriding) to enhance wear resistance and corrosion resistance.

- Employing lightweight and high-strength aluminum alloy for the cylinder body to reduce equipment weight and improve heat dissipation.

- Selecting high-quality materials for key components (such as bearings and seals) to enhance reliability and stability.

Implementation of Intelligent Monitoring and Maintenance

Utilizing sensor technology and the Internet of Things (IoT) to monitor the operating status of retractable electric cylinders in real time, including parameters like displacement, speed, pressure, and temperature. Through data analysis and fault diagnosis algorithms, potential issues can be identified promptly, and corresponding maintenance measures can be taken. For example:

- When the detected wear amount of the lead screw exceeds the set threshold, the system automatically sends an alarm and prompts maintenance or replacement.

- Establishing maintenance records to document operating time, maintenance history, and other information, providing a basis for regular maintenance and replacement to extend service life.

Through process optimization strategies such as controlling algorithm optimization, structural design improvement, suitable material selection, and intelligent monitoring & maintenance, the application performance of retractable electric cylinders in rubber machinery can be further enhanced, promoting the rubber machinery industry toward high efficiency, energy conservation, and intelligence. In the future, with continuous technological advancements, retractable electric cylinders will find broader applications in rubber machinery, and their process optimization will continue to achieve new breakthroughs.