Purchasing hotline:0086-18962115905

上一张

下一张

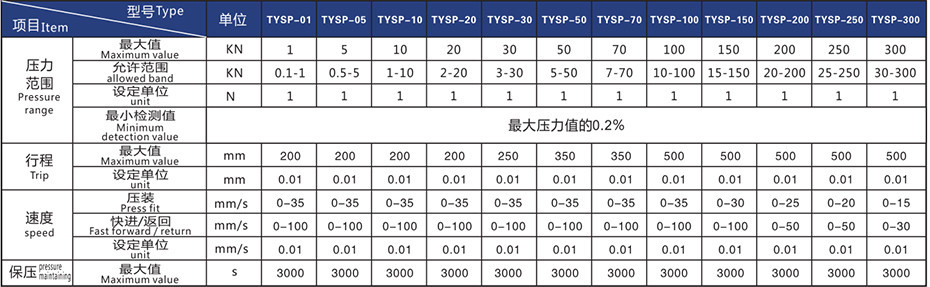

01Suitable for pressing force range 0.5-10KN

02Vertical C-type body, pure steel plate integrated welding, firm, reliable, easy to handle.

03Precision servo integrated system + large display control

04A variety of pressing methods to choose from, real-time curve analysis, accurate control.

05Can save hundreds of different process parameters, data call is convenient.

06Suitable for product testing precision pressing, forming, riveting and other processes.

07High pressing efficiency, easy operation, low noise, small vibration.

08Wide practicability and versatility, can be operated by a single machine or connected to an automatic assembly line.

01A variety of press-assembly modes are available, and the press-assembly program can be customized, stored and called to meet the process requirements of different products.

02Allows a variety of conditions to be set during the press assembly process to control the press speed and stop position or stop pressure, enabling applications such as setting Windows and incremental control.

03Servo press machine closed-loop servo control system, to achieve real-time acquisition and analysis of force and displacement time data, force and displacement monitoring, force and time monitoring; With pressure control, displacement control, speed control, manual control, suitable for all occasions that have strict requirements for the press assembly process.

04Easy parameter setting and programming, real-time data acquisition and output of force and displacement curve. Equipped with tolerance recognition window, automatically judge the press assembly result OK/NG。

05It can save the data in the entire press assembly process to the computer or flash disk to ensure the traceability of product processing data and facilitate the control and management of production quality.

06The servo press machine itself has accurate pressure and displacement control functions, and it is not necessary to apply hard limits when calling different software programs to process products.

Automobile industryEngine assembly press assembly, steering assembly press assembly, differential assembly line, main reducer assembly line, automotive hub unit bearing, etc

Electric machine industryMicromotor assembly (spindle, housing, etc.) Motor assembly (bearing, spindle, etc.)

Electronics industryPress assembly of circuit board components (plug-ins, etc.), press assembly of electronic parts.

Special operationPowder molding, explosive pressing, etc.

Other industriesHome appliance industry, machinery industry and other need precision CNC pressure displacement and pressure force occasions

Related Products

Related Products

Servo presses usually refer to presses that are driven and controlled by servo motors. Including met...

Learn More

Servo presses usually refer to presses that are driven and controlled by servo motors. Including met...

Learn More

Servo presses usually refer to presses that are driven and controlled by servo motors. Including met...

Learn More

Servo presses usually refer to presses that are driven and controlled by servo motors. Including met...

Learn More